Synthetic Gear Lubricants

|

| Severe Gear 75W-90

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles. Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles.

|

Severe Gear 75W-110

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles. Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles.

|

Product Code: SVGQT-EA

|

|

Product Code: SVTQT-EA

|

|

| Severe Gear 75W-140

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles. Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles.

|

75W-90 Long Life Synthetic Gear Lube

Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils. Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils.

|

Product Code: SVOQT-EA

|

|

Product Code: FGRQT-EA

|

|

| 80W-140 Long Life Synthetic Gear Lube

Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils. Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils.

|

Synthetic 80W-90 Gear Lube

For applications specifying SAE 80W-90 conventional gear lube. Provides improved cold flow properties, high viscosity index and heat resistance. Contains an over-treat of high-quality additives, exceeding the minimum standards. Provides excellent wear protection and long equipment life. For applications specifying SAE 80W-90 conventional gear lube. Provides improved cold flow properties, high viscosity index and heat resistance. Contains an over-treat of high-quality additives, exceeding the minimum standards. Provides excellent wear protection and long equipment life.

|

Product Code: FGO05-EA

|

|

Product Code: AGLQT-EA

|

|

| Universal Synthetic Marine Gear Lube

True marine gear performance. Provides superior protection from shock loading. Resists foam and retains extreme-pressure qualities even when subjected to 10% water contamination. For use in outboard lower units,

sterndrives, V-drives, bow and tunnel thrusters and marine transmissions Excellent for use in ATVs. True marine gear performance. Provides superior protection from shock loading. Resists foam and retains extreme-pressure qualities even when subjected to 10% water contamination. For use in outboard lower units,

sterndrives, V-drives, bow and tunnel thrusters and marine transmissions Excellent for use in ATVs.

|

Slip Lock Differential Additive

Formulated with advanced friction modifiers. Eliminates gear-housing chatter in cars, trucks and SUVs equipped with limited-slip, positraction and locking differentials. For use with both synthetic and petroleum gear lubricants and safely replaces manufacturer-recommended friction modifiers. Formulated with advanced friction modifiers. Eliminates gear-housing chatter in cars, trucks and SUVs equipped with limited-slip, positraction and locking differentials. For use with both synthetic and petroleum gear lubricants and safely replaces manufacturer-recommended friction modifiers.

|

Product Code: AGMTB-EA

|

|

Product Code: ADATB-EA  |

|

| Bottle Hand Pump

Specifically designed to fit AMSOIL quart, gallon and Twin Pack bottles. Guarantees efficient, quick dispensing of AMSOIL gear oils, transmission fluids and any oil that may need to be pumped. Great for fluid fills in differentials, transmissions, transaxles, boat lower units and boat

sterndrives. Specifically designed to fit AMSOIL quart, gallon and Twin Pack bottles. Guarantees efficient, quick dispensing of AMSOIL gear oils, transmission fluids and any oil that may need to be pumped. Great for fluid fills in differentials, transmissions, transaxles, boat lower units and boat

sterndrives.

|

|

Product Code: G2039-EA  |

|

|

Synthetic Racing Gear Lube

|

|

Severe Gear SAE 190

Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life. Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life.

|

Severe Gear SAE 250

Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life. Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life.

|

Product Code: SRNQT-EA  |

|

Product Code: SRTQT-EA  |

|

SEVERE GEAR® Synthetic Extreme

Pressure (EP) Lubricants

75W-90 (SVG), 75W-110 (SVT) &

75W-140 (SVO)

Formulated for the severe operating

conditions of today’s

pick-up trucks, SUVs, heavy equipment and other hard working vehicles.

Product Description

AMSOIL SEVERE GEAR®

Synthetic Extreme Pressure (EP) Lubricants are premium grade gear oils

specifically engineered for maximum performance in severe duty applications.

These state-of-the-art AMSOIL formulations feature an exclusive blend of high

viscosity, shear stable synthetic base oils and an extra treatment of

high-performance additives. AMSOIL SEVERE GEAR®

Synthetic EP Lubricants maintain their viscosity for long-lasting protection

against metal-to-metal contact. The proprietary AMSOIL additives form an

iron-sulfide barrier coating on gear surfaces, providing the ultimate line of

defense against wear, pitting and scoring. AMSOIL SEVERE GEAR®

lubricants help prevent “thermal runaway” — a phenomenon caused by a

lubricant’s inability to control friction and increased heat under high-stress

conditions. By controlling thermal runaway, AMSOIL SEVERE GEAR®

Synthetic EP Lubricants inhibit rapid lubricant degradation and component

damage. Equipment runs better and lasts longer with AMSOIL SEVERE GEAR®

Synthetic EP Lubricants.

Performance

AMSOIL SEVERE GEAR®

provides performance beyond that possible with conventional gear oil. These

AMSOIL custom products offer superior gear and bearing protection, better

friction and heat reduction, increased efficiency and extended service life.

Superior Film Strength

Superior Film Strength

Controls Thermal

Runaway

Controls Thermal

Runaway

Rust and Corrosion

Protection

Rust and Corrosion

Protection

Reduced Operating

Temperatures

Reduced Operating

Temperatures

Improved Efficiency

Improved Efficiency

Longer Oil, Seal,

& Equipment Life

Longer Oil, Seal,

& Equipment Life

Temperature Extremes

AMSOIL SEVERE GEAR® EP

lubricants excel in hot and cold temperature extremes. By design, they resist

breakdown from high heat, preventing acids and carbon/varnish formation. Their

waxfree construction also improves cold flow properties, improving fuel economy

and cold weather shifting.

Applications

AMSOIL SEVERE GEAR®

Synthetic EP Lubricants are excellent for severe applications, such as towing,

hauling, steep hill driving, commercial use, plowing, racing, off-road use,

rapid acceleration, frequent stop-and-go operation and high ambient

temperatures. Higher horsepower, towing and hauling capabilities of modern

vehicles make turbo diesel pick-ups, SUVs, vans and delivery/utility vehicles

especially prone to severe service. Other severe duty vehicles include light,

medium and heavy-duty trucks, buses, heavy equipment, 4X4s, tow trucks, race

cars, tractors, and motorhomes.

For product service life in differentials, consult your

owner’s manual or the Original Equipment Manufacturer (OEM) to establish the

application, NORMAL or SEVERE.

| |

NORMAL |

SEVERE |

Cars, SUV,

Light & Medium Duty Trucks |

Drain at 100,000 miles of service or

according to the owner’s manual, whichever is longer |

Drain at 50,000 miles of service or

according to the owner’s manual, whichever is longer |

|

Heavy Duty Class 8 Line Haul |

Follow the OEM drain interval (miles or

hours) for synthetic oil up to 250,000 miles or 3 years, whichever comes

first. Otherwise, drain at twice the OEM interval for conventional oil. |

|

Heavy Duty Off-Road Vocational |

Follow the OEM drain interval (miles or

hours) for synthetic oil up to 120,000 miles or 1 year, whichever comes

first. Otherwise, drain at twice the OEM interval for conventional oil. |

For product service life in non-differential applications,

consult owner’s manual or the OEM for either normal or severe synthetic oil

service intervals. Where service intervals are unavailable, drain at twice the

interval for conventional oil. Gear oils should be changed more frequently when

operating vehicles or equipment in dusty or dirty conditions unless the gear

system is properly sealed and equipped with membrane type breathers.

Note: AMSOIL does not support extended drain intervals

where water contamination occurs. Check and service the gear oil frequently when

water contamination is possible.

Recommended for use in differentials, manual transmissions and

other gear applications requiring any of the following specifications: API

GL-5, MT-1, MIL-PRF-2105E, Dana SHAES 234 (Formerly Eaton PS-037), Mack GO-J, or

the differential (hypoid) gear oil specifications from all domestic and foreign

manufacturers such as GM, Ford and Daimler Chrysler. Can also be used in axles

where an API GL-4 lubricant is recommended.

AMSOIL SEVERE GEAR® (75W-90)

provides superior performance and replaces competitors’ 75W-90 and 80W-90

gear oils. It delivers the best fuel efficiency and cold temperature performance

of the SEVERE GEAR oils.

AMSOIL SEVERE GEAR® (75W-110)

provides superior performance and replaces competitors’ 75W-110, 75W-90

and 80W-90 gear oils. It delivers better viscosity protection than SEVERE GEAR

75W-90 and better fuel efficiency than SEVERE GEAR 75W-140.

AMSOIL SEVERE GEAR® (75W-140)

provides superior performance and replaces competitors’ 75W-140, 80W-140

and 85W-140 gear oils. Use where these viscosities are required by OEMs and

where maximum viscosity protection is needed for extreme severe-duty

applications.

AMSOIL SEVERE GEAR® is

compatible with conventional and synthetic gear oils. Mixing AMSOIL gear oils

with other oils, however, will shorten the oil life expectancy and reduce the

performance benefits. AMSOIL does not support extended drain intervals

where oils have been mixed. Aftermarket oil additives, other than those

specified by AMSOIL, are not recommended for use with AMSOIL gear oils.

AMSOIL SEVERE GEAR® is

compatible with most limited slip differentials. If limited slip differential

chatter occurs, add AMSOIL Slip-Lock™ friction modifier additive.

Keep Out of Reach of Children. Don’t pollute. Return used oil

to collection centers.

|

TYPICAL TECHNICAL PROPERTIES

AMSOIL SEVERE GEAR® Synthetic Extreme Pressure (EP)

Lubricants 75W-90, 75W-110 & 75W-140 |

| |

SAE 75W-90 (SVG) |

SAE 75W-110 (SVT) |

SAE 75W-140 (SVO) |

| Kinematic Viscosity @ 100°C, cSt (ASTM

D-445) |

16.4 |

20.4 |

25.7 |

| Kinematic Viscosity @ 40°C, cSt (ASTM

D-445) |

108.79 |

143.7 |

185.6 |

| Viscosity Index |

163 |

164 |

173 |

| Brookfield Viscosity, cP (150,000 Max) @-40°C |

70,958 |

118,728 |

124,210 |

| Flash Point, °C (°F) (ASTM D-92) 150°C

Min. |

218 (424) |

220 (428) |

210 (410) |

| Pour Point, °C (°F) (ASTM D-97) |

-51 (-60) |

-48 (-54) |

-48 (-54) |

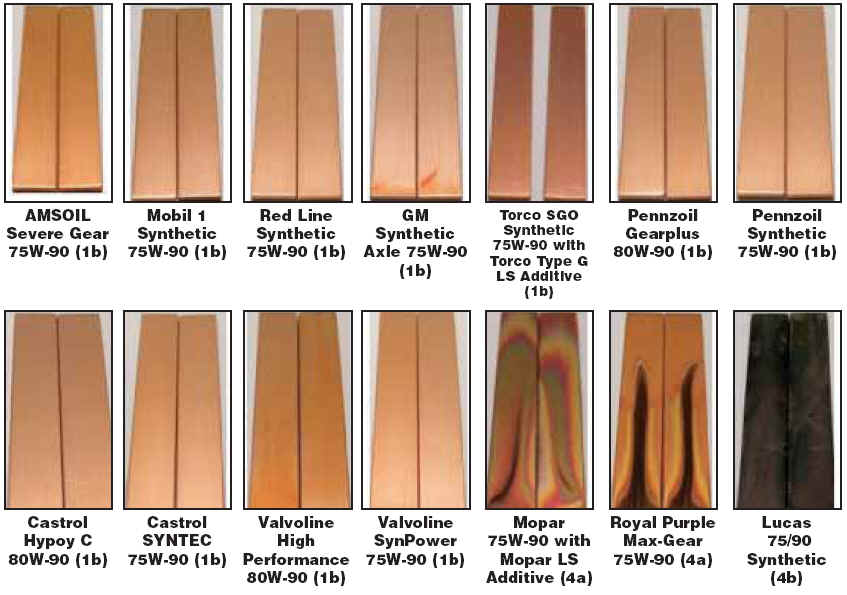

| Copper Corrosion (ASTM D-130) 1b Max @ 121

°C (250°F) / 3hr |

1b |

1b |

1b |

| Falex Procedure B (ASTM D-3233) (failure

load, lbf.) |

1500 |

1500 |

1500 |

| Foam Stability (ASTM D-892) (20/50/20

maximum) |

0/0/0 |

0/0/0 |

0/0/0 |

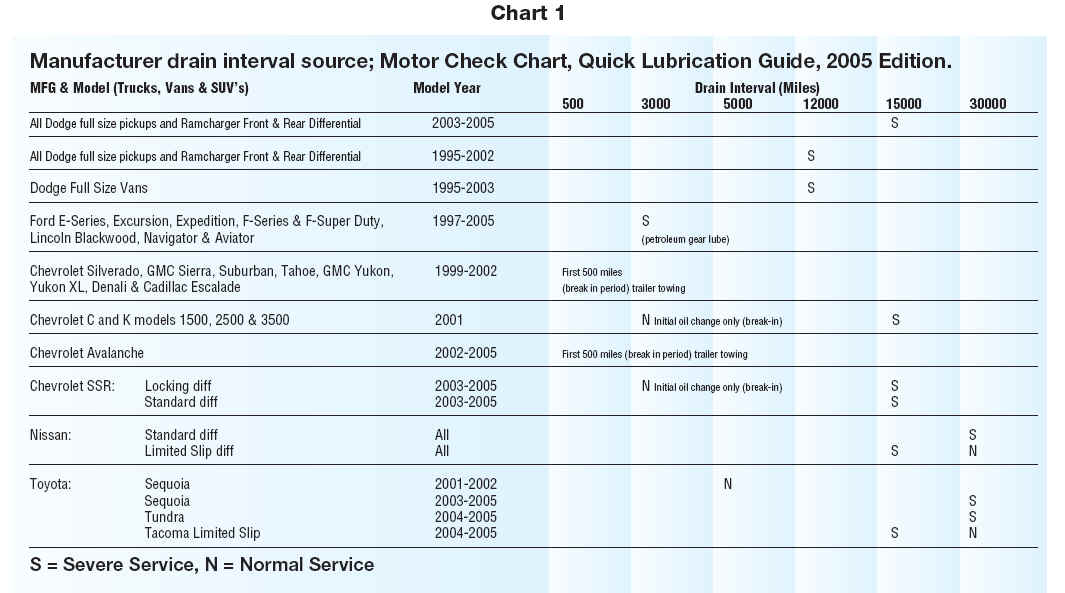

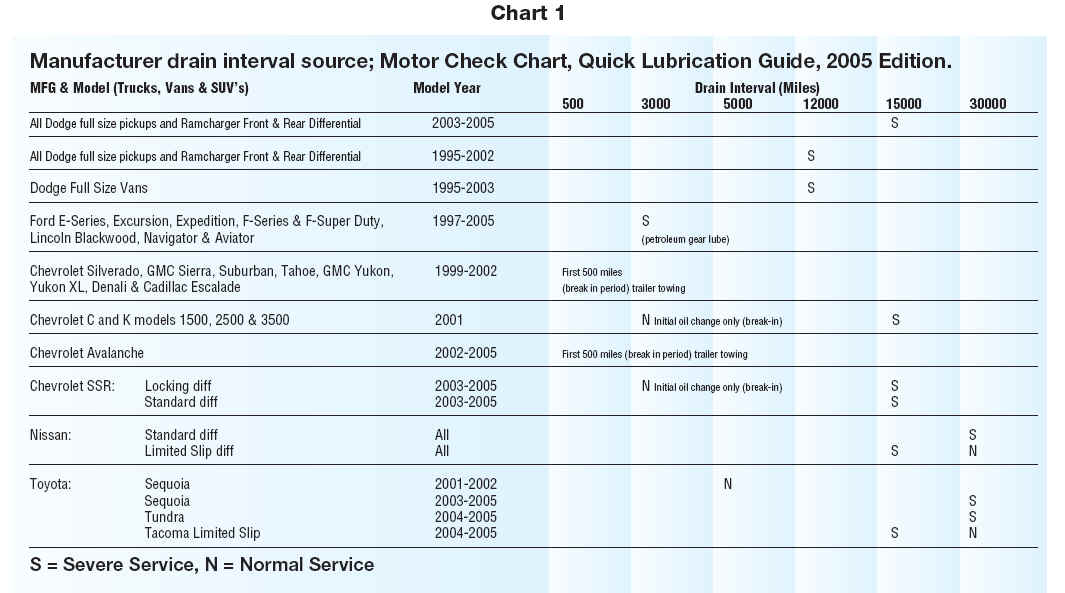

Change Gear Lube After Break-In Period

for Long Differential Life

Unbeknownst to many motorists, most

differential wear occurs during the break-in period. AMSOIL Dealers can do

customers and prospects a service, by

encouraging them to change their gear lube following the break-in period

in order to reduce wear and extend differential life.

Motorists know when they’re supposed to

change their motor oil. They have oil life monitors, oil change centers

and commercials all telling them when it’s time for an oil change.

Differential oil changes, on the other hand, often get overlooked. Many

people don’t even think of the differential when performing routine

maintenance on their vehicles and don’t realize four-wheel drive trucks

have two differentials and a transfer case that all require service. In

fact, according to one quick lube company, only one to two percent of

their customers purchase a differential gear lube change. Most

differential wear occurs during the break-in period. Because differentials

are not equipped with filters, break-in metals are suspended in the oil,

causing increased wear as the particles mesh between the gears. Hauling

heavy loads and towing heavy trailers cause additional stress to the

differential during the break-in period and can cause premature

differential damage or failure. Changing the gear lube after the break-in

period (about 3,000 miles) is a low-cost maintenance investment that

provides a significant payoff, including greatly reduced wear, extended

differential gear and bearing life and protection for expensive vehicle

investments. Auto manufacturers recognize the importance of draining

abrasive break-in materials. As seen in Chart 1, some manufacturers

recommend an initial drain interval of between 500 and 3,000 miles.

Differential internal components consist of six gears (one pinion, one ring, two side and two

spider gears), six bearings (two pinion, two carrier and two axle) and

sometimes include a clutch setup for limited slip performance. All of

these parts require high quality, clean gear oil in order to perform at an

optimal level. Most pickup trucks, SUVs and vans operate in severe service

conditions, including towing, hauling, steep hill driving, commercial use,

plowing, racing, offroad use, rapid acceleration, frequent

stop and go operation and high ambient temperatures. These severe service

operating conditions subject the differential to extreme pressures and

operating temperatures. Few vehicles such as turbo diesel trucks and

vehicles with V-10 engines boast more horsepower and

torque than their predecessors, but differential designs have remained

virtually unchanged. Differentials today are subjected to severe duty

service and encounter more stress and heat than was seen only a few years

ago. Modern gear oils are faced with the challenge of providing adequate

wear protection during severe service operating conditions, while also

providing maximum fuel efficiency. In fact, according to a 2005 SAE paper

entitled Breaking the Viscosity Paradigm: Formulating Approaches for

Optimizing Efficiency and Vehicle Life, “Concurrent with the strong

drive toward better fuel economy, consumers have been demanding increased

performance, which has required axle lubricants with enhanced durability

protection and lower operating temperatures. There has been a 34% increase

in engine horsepower over the last decade, while axle gear sizes have

remained constant, sump capacities have been lowered, and drain intervals

extended. In the light truck segment there has been a 93% horsepower

increase since 1981.” Further evidence of stress and increased

temperatures during the differential

break-in period is documented in a 2005 SAE paper entitled The Effect of Heavy Loads on Light Duty Vehicle Axle Operating

Temperature. A light duty GM truck towing 14,000 pounds was driven

from Orange County, Calif. to the Nevada state line. The test was

conducted with both a new axle and a broken-in axle.

Motorists know when they’re supposed to

change their motor oil. They have oil life monitors, oil change centers

and commercials all telling them when it’s time for an oil change.

Differential oil changes, on the other hand, often get overlooked. Many

people don’t even think of the differential when performing routine

maintenance on their vehicles and don’t realize four-wheel drive trucks

have two differentials and a transfer case that all require service. In

fact, according to one quick lube company, only one to two percent of

their customers purchase a differential gear lube change. Most

differential wear occurs during the break-in period. Because differentials

are not equipped with filters, break-in metals are suspended in the oil,

causing increased wear as the particles mesh between the gears. Hauling

heavy loads and towing heavy trailers cause additional stress to the

differential during the break-in period and can cause premature

differential damage or failure. Changing the gear lube after the break-in

period (about 3,000 miles) is a low-cost maintenance investment that

provides a significant payoff, including greatly reduced wear, extended

differential gear and bearing life and protection for expensive vehicle

investments. Auto manufacturers recognize the importance of draining

abrasive break-in materials. As seen in Chart 1, some manufacturers

recommend an initial drain interval of between 500 and 3,000 miles.

Differential internal components consist of six gears (one pinion, one ring, two side and two

spider gears), six bearings (two pinion, two carrier and two axle) and

sometimes include a clutch setup for limited slip performance. All of

these parts require high quality, clean gear oil in order to perform at an

optimal level. Most pickup trucks, SUVs and vans operate in severe service

conditions, including towing, hauling, steep hill driving, commercial use,

plowing, racing, offroad use, rapid acceleration, frequent

stop and go operation and high ambient temperatures. These severe service

operating conditions subject the differential to extreme pressures and

operating temperatures. Few vehicles such as turbo diesel trucks and

vehicles with V-10 engines boast more horsepower and

torque than their predecessors, but differential designs have remained

virtually unchanged. Differentials today are subjected to severe duty

service and encounter more stress and heat than was seen only a few years

ago. Modern gear oils are faced with the challenge of providing adequate

wear protection during severe service operating conditions, while also

providing maximum fuel efficiency. In fact, according to a 2005 SAE paper

entitled Breaking the Viscosity Paradigm: Formulating Approaches for

Optimizing Efficiency and Vehicle Life, “Concurrent with the strong

drive toward better fuel economy, consumers have been demanding increased

performance, which has required axle lubricants with enhanced durability

protection and lower operating temperatures. There has been a 34% increase

in engine horsepower over the last decade, while axle gear sizes have

remained constant, sump capacities have been lowered, and drain intervals

extended. In the light truck segment there has been a 93% horsepower

increase since 1981.” Further evidence of stress and increased

temperatures during the differential

break-in period is documented in a 2005 SAE paper entitled The Effect of Heavy Loads on Light Duty Vehicle Axle Operating

Temperature. A light duty GM truck towing 14,000 pounds was driven

from Orange County, Calif. to the Nevada state line. The test was

conducted with both a new axle and a broken-in axle.

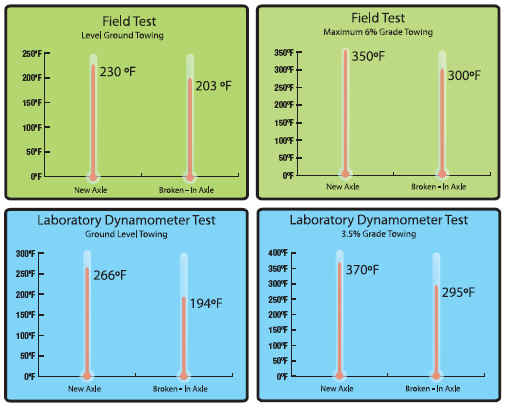

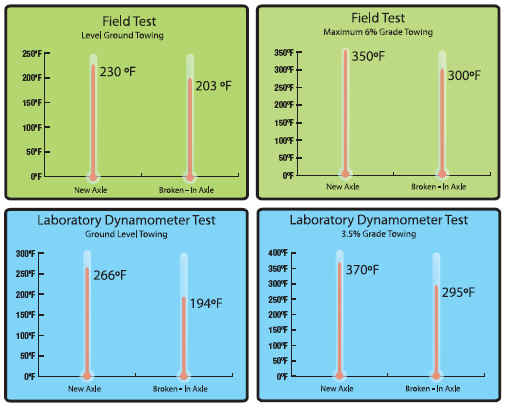

Over level ground towing, oil temperature

was measured at 230 degrees F in the new axle and 203 degrees F in the

broken-in axle. Oil temperature over the most grueling portion of the trip, during which a maximum 6% grade was encountered,

revealed the new axle was operating at 350 degrees F and the broken-in axle was operating at 300 degrees F. Laboratory dynamometer test results

simulating a truck hauling a trailer provided similar results, with level ground towing temperatures recorded at 266 degrees F with the new axle and

194 degrees F with the broken-in axle and towing temperatures (at a 3.5% grade) recorded at

370 degrees F with the new axle and 295 degrees F

with the broken-in axle.

Over level ground towing, oil temperature

was measured at 230 degrees F in the new axle and 203 degrees F in the

broken-in axle. Oil temperature over the most grueling portion of the trip, during which a maximum 6% grade was encountered,

revealed the new axle was operating at 350 degrees F and the broken-in axle was operating at 300 degrees F. Laboratory dynamometer test results

simulating a truck hauling a trailer provided similar results, with level ground towing temperatures recorded at 266 degrees F with the new axle and

194 degrees F with the broken-in axle and towing temperatures (at a 3.5% grade) recorded at

370 degrees F with the new axle and 295 degrees F

with the broken-in axle.

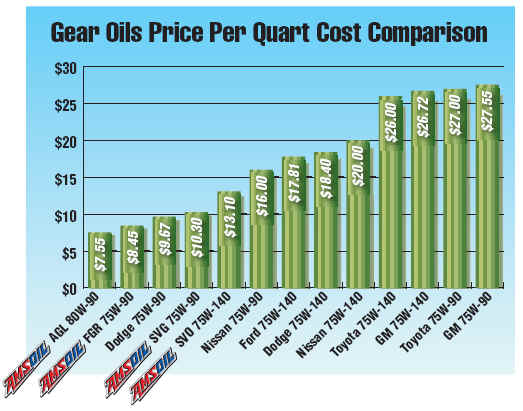

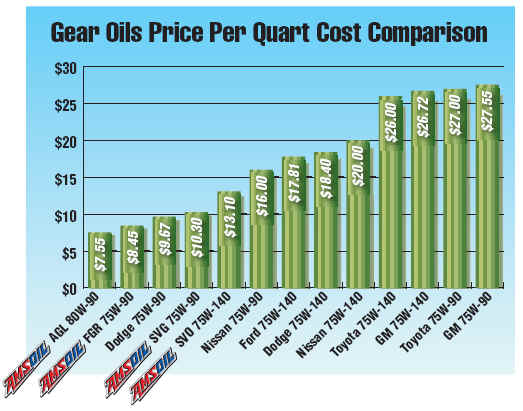

AMSOIL SEVERE GEAR™ 75W-90 and 75W-140

Synthetic Gear Lubes are formulated for severe service applications,

protecting differential gears for extended drain intervals of up to 50,000

miles in severe service and 100,000 miles in normal service, or longer

where specified by the vehicle manufacturer. Formulated with shear stable

synthetic base stocks and an extra treatment of additives, SEVERE GEAR™

Gear Lubes provide unsurpassed wear protection and friction reduction,

while their excellent thermal stability prevents thermal runaway, a

phenomenon caused by a lubricant’s inability to control friction and

increased heat under high stress conditions. AMSOIL

SEVERE GEAR™ Synthetic Gear Lubes are recommended for turbo diesel

pick-ups, SUVs, vans, delivery/utility vehicles, light, medium and

heavy-duty trucks, buses, heavy equipment, 4x4s, tow trucks, race cars,

tractors and motor homes. AMSOIL Synthetic Gear Lubes save motorists money

through extended drain intervals, and they also cost less per quart

compared to many competing OEM gear lubes:

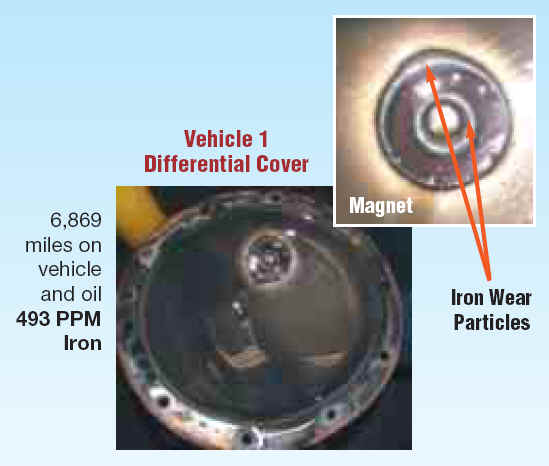

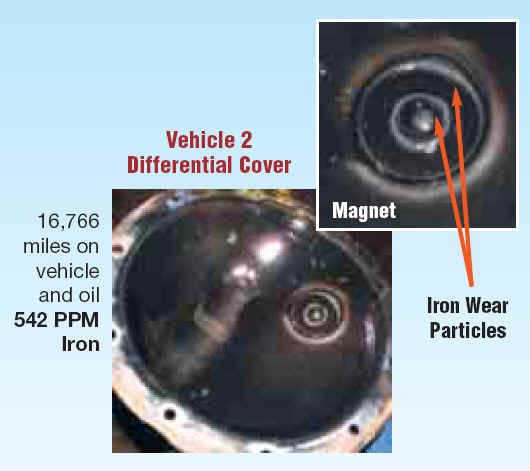

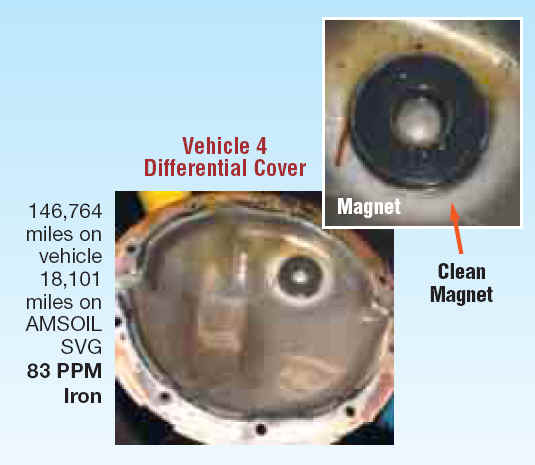

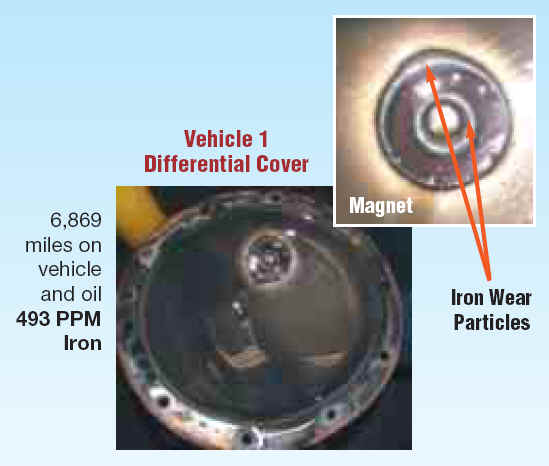

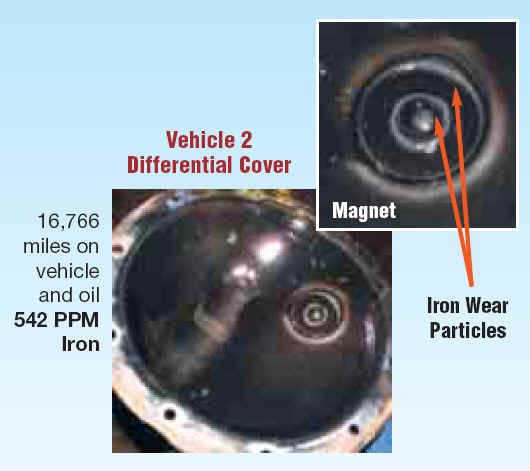

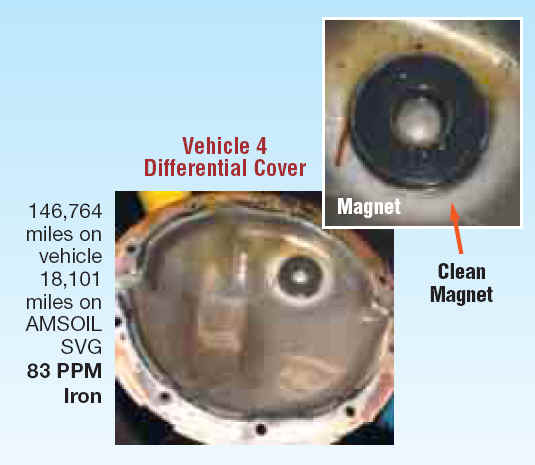

A test on four separate vehicles further

demonstrated the importance of changing the factory-fill gear lube

within the first few thousand miles. Oil analysis results revealed most of

the wear in vehicle one occurred within the first 6,869 miles. Despite

higher mileages, vehicles two and three only showed slightly higher iron

wear than vehicle one. Vehicle four was the only vehicle which had the

factory-fill oil changed to AMSOIL synthetic gear lube, and despite

significantly higher mileage than the first three vehicles, it showed a

significantly lower level of wear. The chart above and photos below provide

visual evidence of the wear materials present in the differentials of each

vehicle. The photos clearly show that the heaviest amount of wear occurs

early in the break-in period. Wear is

significantly reduced when the gear lube is changed to AMSOIL synthetic

gear lube following the break-in period.

Most customers are unaware of the

importance of changing the factory-fill gear oil within the first few

thousand miles. AMSOIL Synthetic Gear Lubes are ideal for owners of new

vehicles.

|

|

|

|

|

|

|

My own 2004 GMC Canyon after 2

years on OEM Fluid. |

|

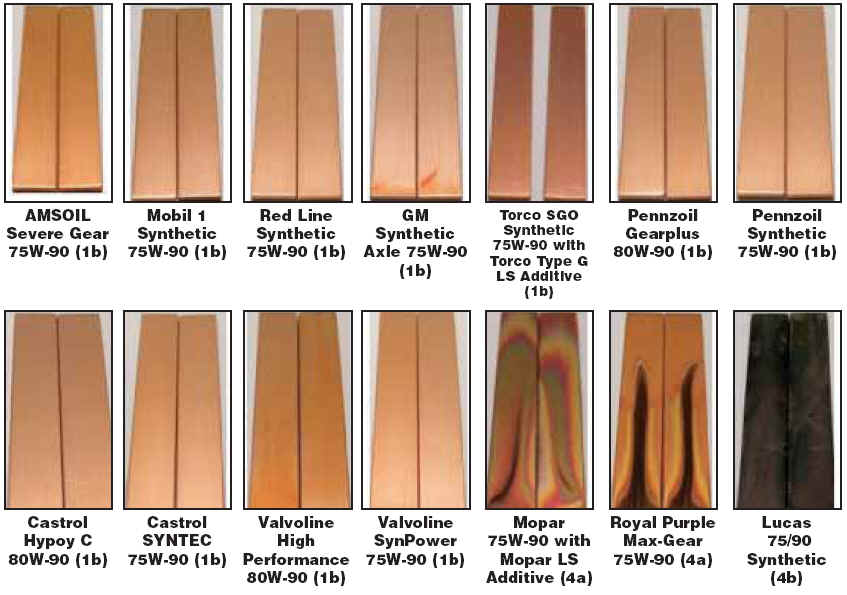

“A Study of Automotive Gear Lubes”

This comprehensive study of gear lubricants will undoubtedly

shake up the marketplace. Fourteen of the most popular brands of gear lube were

tested at an independent laboratory in areas such as pour point, 4-ball EP weld

point, 4-ball EP load-wear index, Falex extreme pressure and many other tests

used in meeting API GL-5 performance requirements and SAE J306 viscosity

requirements.

The purpose of the Gear Oil White Paper is to inform consumers

about the increasingly severe conditions under which differentials operate and

to provide data reflecting the quality and cost differences of many popular

synthetic and petroleum gear lubes. With this information, consumers are better

prepared to make informed decisions when purchasing gear lubricants. All

performance testing was conducted by an independent laboratory.

Physical-property testing (viscosity, viscosity index, pour point and foaming

after oxidation) was conducted in-house. Gear lube pricing was obtained from the

manufacturers or distributors.

This no-frills study is designed to help consumers make informed

decisions when selecting gear oils. There is no hype and no sales pitch -- just

facts. Never before has so much information on gear oils been delivered in one

easy to understand source.

Download the PDF version of the Gear Oil White Paper by clicking

this link: Printable

PDF Version (481KB)

Report problems to Webmaster

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles.

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles. Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles.

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles. Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles.

Engineered for high-demand applications, including trailer towing, heavy hauling, 4X4 off-road driving, commercial use and racing. Protects gears and bearings from scoring and wear. Excellent cold-flow properties. Outperforms all conventional gear oils. Recommended for all types of vehicles. Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils.

Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils. Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils.

Engineered for extended drain intervals up to 500,000 miles as set by equipment manufacturers for over-the-road trucks and heavy equipment. Provides long life in passenger cars and trucks. Excellent all season summer and winter performance. Outperforms all conventional gear oils. For applications specifying SAE 80W-90 conventional gear lube. Provides improved cold flow properties, high viscosity index and heat resistance. Contains an over-treat of high-quality additives, exceeding the minimum standards. Provides excellent wear protection and long equipment life.

For applications specifying SAE 80W-90 conventional gear lube. Provides improved cold flow properties, high viscosity index and heat resistance. Contains an over-treat of high-quality additives, exceeding the minimum standards. Provides excellent wear protection and long equipment life. True marine gear performance. Provides superior protection from shock loading. Resists foam and retains extreme-pressure qualities even when subjected to 10% water contamination. For use in outboard lower units,

sterndrives, V-drives, bow and tunnel thrusters and marine transmissions Excellent for use in ATVs.

True marine gear performance. Provides superior protection from shock loading. Resists foam and retains extreme-pressure qualities even when subjected to 10% water contamination. For use in outboard lower units,

sterndrives, V-drives, bow and tunnel thrusters and marine transmissions Excellent for use in ATVs. Formulated with advanced friction modifiers. Eliminates gear-housing chatter in cars, trucks and SUVs equipped with limited-slip, positraction and locking differentials. For use with both synthetic and petroleum gear lubricants and safely replaces manufacturer-recommended friction modifiers.

Formulated with advanced friction modifiers. Eliminates gear-housing chatter in cars, trucks and SUVs equipped with limited-slip, positraction and locking differentials. For use with both synthetic and petroleum gear lubricants and safely replaces manufacturer-recommended friction modifiers. Specifically designed to fit AMSOIL quart, gallon and Twin Pack bottles. Guarantees efficient, quick dispensing of AMSOIL gear oils, transmission fluids and any oil that may need to be pumped. Great for fluid fills in differentials, transmissions, transaxles, boat lower units and boat

sterndrives.

Specifically designed to fit AMSOIL quart, gallon and Twin Pack bottles. Guarantees efficient, quick dispensing of AMSOIL gear oils, transmission fluids and any oil that may need to be pumped. Great for fluid fills in differentials, transmissions, transaxles, boat lower units and boat

sterndrives. Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life.

Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life. Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life.

Recommended for racing applications that require heavier-viscosity gear lubricants. Engineered specifically for the demands of severe racing conditions. Provides improved flow over conventional oils, reducing viscous drag and power loss. The ultimate line of defense against wear, pitting and scoring. Extends gear life.

Motorists know when they’re supposed to

change their motor oil. They have oil life monitors, oil change centers

and commercials all telling them when it’s time for an oil change.

Differential oil changes, on the other hand, often get overlooked. Many

people don’t even think of the differential when performing routine

maintenance on their vehicles and don’t realize four-wheel drive trucks

have two differentials and a transfer case that all require service. In

fact, according to one quick lube company, only one to two percent of

their customers purchase a differential gear lube change. Most

differential wear occurs during the break-in period. Because differentials

are not equipped with filters, break-in metals are suspended in the oil,

causing increased wear as the particles mesh between the gears. Hauling

heavy loads and towing heavy trailers cause additional stress to the

differential during the break-in period and can cause premature

differential damage or failure. Changing the gear lube after the

Motorists know when they’re supposed to

change their motor oil. They have oil life monitors, oil change centers

and commercials all telling them when it’s time for an oil change.

Differential oil changes, on the other hand, often get overlooked. Many

people don’t even think of the differential when performing routine

maintenance on their vehicles and don’t realize four-wheel drive trucks

have two differentials and a transfer case that all require service. In

fact, according to one quick lube company, only one to two percent of

their customers purchase a differential gear lube change. Most

differential wear occurs during the break-in period. Because differentials

are not equipped with filters, break-in metals are suspended in the oil,

causing increased wear as the particles mesh between the gears. Hauling

heavy loads and towing heavy trailers cause additional stress to the

differential during the break-in period and can cause premature

differential damage or failure. Changing the gear lube after the  Over level ground towing, oil temperature

was measured at 230 degrees F in the new axle and 203 degrees F in the

broken-in axle. Oil temperature over the most grueling portion of the trip, during which a maximum 6% grade was encountered,

revealed the new axle was operating at 350 degrees F and the broken-in axle was operating at 300 degrees F. Laboratory dynamometer test results

simulating a truck hauling a trailer provided similar results, with level ground towing temperatures recorded at 266 degrees F with the new axle and

194 degrees F with the broken-in axle and towing temperatures (at a 3.5% grade) recorded at

370 degrees F with the new axle and 295 degrees F

with the broken-in axle.

Over level ground towing, oil temperature

was measured at 230 degrees F in the new axle and 203 degrees F in the

broken-in axle. Oil temperature over the most grueling portion of the trip, during which a maximum 6% grade was encountered,

revealed the new axle was operating at 350 degrees F and the broken-in axle was operating at 300 degrees F. Laboratory dynamometer test results

simulating a truck hauling a trailer provided similar results, with level ground towing temperatures recorded at 266 degrees F with the new axle and

194 degrees F with the broken-in axle and towing temperatures (at a 3.5% grade) recorded at

370 degrees F with the new axle and 295 degrees F

with the broken-in axle.